Types Of Products

Steam Assisted Flares

This type of flare utilizes the a steam injection to be mixed with gas at the flare tip in order to reduce smoke emission and radiation levels. Steam in high temperature will convert incomplete gas product such as CO to CO2. For cold countries, steam-assisted type is suitable for freeezing protection.

Air Assisted Flares

Heavy hydrocarbon has great tendency to produce smoke because unburnt hydrocarbon or gas particles. In principle of stoichiometric combustion of relief can be achieved by installing blowers to provide excess air at the flare tip. This excess air is required to create a complete combustion and smokeless flaring.

Unassisted Flare

When the gas has good composition such as many light hydrocarbon content and high LHV, the application fo this flare type will be the main consideration after conducting the engineering simulation and calculation. it has lower investment cost and maintenance cost than other assisted-flare.

Combined HP & LP Flare

In one compact design, two types of gases which are low pressure gas and high pressure gas are burnt in a single flare tip. Designed with integrated turbulence swirl plates, it improves the mixing between high pressure gas and low pressure gas with surrounding air to create a turbulence effect inside the flame. Final goal in this process is complete combustion with smokeless flame.

Offshore Flares

Any type of elevated flare can be applicable for offshore facilities. It considers the material of flare tip from high resistant of sour condition (corrosivity) and weather condition.

Pit Flares>

A pit flare is installed only for onshore application and generally intermittent operation. It is generally used to burn gas with some liquid content.

Enclosed Ground Flares

Enclosed ground flare hide its flame inside the enclosed wall which is lined with ceramic fibre refactory to greatly reduce the high temperature burning, noise and luminosity. Very suitable for facility near residential or local enviromental regulations do not permit to have a visible flame or when there is no adequate space to install another type of flare.

Multipoint Ground Flares

Designed with several array of small pipe flare tip, installed vertically, and having a height of about 1.5 meters, it provides more efficient combustion through improved air entrainment and reduce flame length. The result is improved combustion with lower smoke emission and radiation levels than a comparable large single tip.

Low BTU Flares

Some gases contains composition which has low lower heating value (LHV), affects the gas is difficult to be burnt as minimum lower heating value of gas should be 200 Btu/scf. To increase the LHV, a gas injection into the flame through manifold or jets sprayer is required. For high pressure gas, its kinetic energy can be used to entrain additional air by piping it separately to the flare tip.

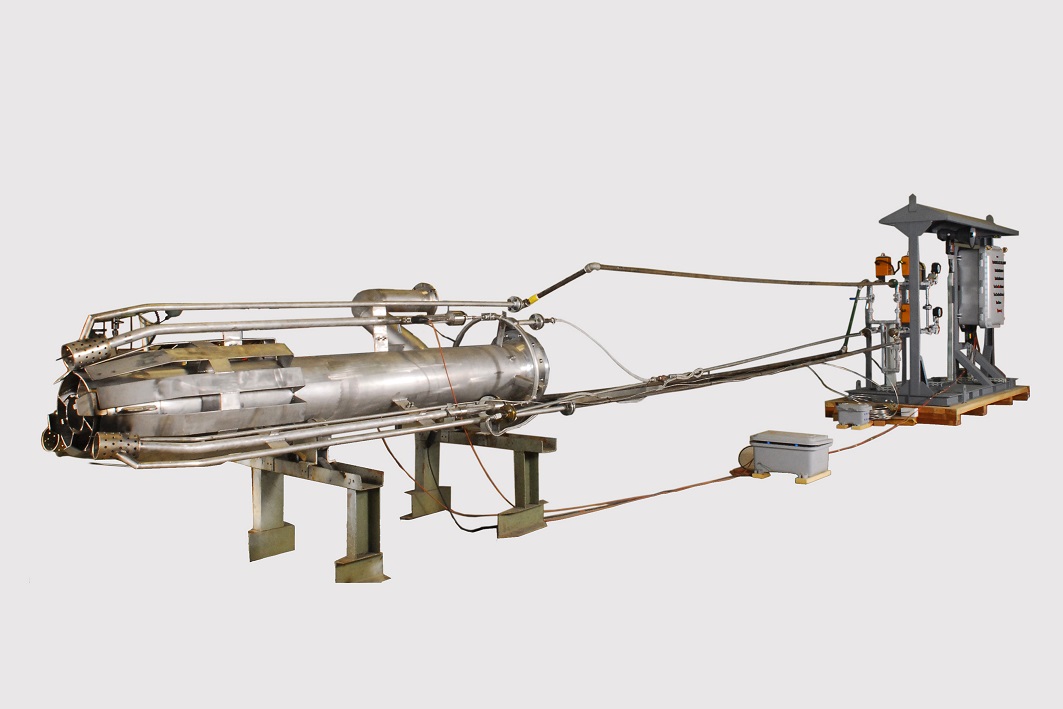

Portable Flares

A portable flare is normally used for temporary flaring, for instance well test burner. This flare can be mobilized from one area to others. Portable flare is consist of Stack and ignition system that complete with battery and LPG bottles that mounted on a trailer. This stack can be self-supporting or guyed wire.

Venting system

This vent is designed same with flare design type, radiation and noise shall be considered in this vent stack design, but vent stack is not completed with ignition system. The waste gas is only vented without flaring. Some safety devices accessories are usually included for vent system such as Flame arrestor, CO2 Snuffing system and spray system with deluge valve. Kotaminyak can supply Vent Stack only without any accessories and Vent stack package complete with it’s safety devices.

FLARE ACCESSORIES:

We also provide a wide array of accessories to complete our solution packages:

High Stability Pilots

Velocity Seal

Knock-Out Drum

Liquid Seal Drum

Custom Manual/Automatic Ignition Control System

Aircraft Warning Lights

Flame/Smoke Monitor

Emission Monitoring System

VALUE ADDED SERVICES

Flare Internusa also includes the following offering packages for a complete solution:

SPARE PARTS

Carrying ample inventory to supply wide array of flare components such as flare tips, ignition system, valves, cables, and others with guaranteed availability.

INSTALLATION

With strong management capabilities, including commissioning, we are confident in delivering smooth and timely project execution.

Installation capability includes:

Guy-Wired Support, Self-Support, Off-Shore Application, and others.

RENTAL

Offering a selection of stand-by, portable various flare sizes. Particularly useful during emergency/shutdown situations, temporary replacements, or one-time flaring needs.

MAINTENANCE/RECONDITION

Providing preventive maintenance, corrective maintenance as well as comprehensive repair/reconditioning into as-new condition. Our service expertise includes:

Analysis and troubleshooting, feasibility studies, inspection report, dismantle/install, transport, inspect/testing, major/minor repairs, on-call emergency, and others.

CONSULTING/ANALYSIS

Performing in-depth system in addition to identifying design improvements/upgrade to optimize flare system operation.

DESIGN/COMPUTING

Using computer-aided engineering software; accurate and customized designs are produced along with various scenarios that can be generated to simulate the perfect flare system.

ENCLOSED GROUND FLARE

Controlled Emission

Insulated Design

Minimal Noise

Suitable for industries located adjacent to residential areas

Enclosed flare conceals fire on the enclosed wall which is lined up with refractory, thus it has more benefit than open flare. Due to its insulated design, enclosed flare not only offers minimal noise and heat but also reduces radiation.

Characterized by smokeless combustion, the enclosed flare is perfectly suitable for industries located to adjacent to communities.

Enclosed flare burns the unwanted gas from a burner or burners placed above ground and resulting flames are hidden from sight by a surrounding wall or chamber. The top of the chamber is open to the atmosphere and allowance is made at the bottom of the chamber to permit the ingress of combustion air.

Ladder and service platforms may be constructed all the way to the top of the chamber in order to access instrumentations and for stack emissions sampling.

The enclosed flare can achieve higher combustion and destruction efficiencies due to the flare flame being contained in the combustion chamber. Therefore, the design must accurately accounts for the air inflow to the combustion chamber and for the ourflow of hot flue gases from the combustion chamber. The airflow can be either by natural draft or forced draft.

Natural draft airflow is controlled by the use of dampers or other means. This type of enclosed flare normally uses wind fence to mitigate the potential of the wind to upset air and flue gas flows during the combustion process as well as to prevent unauthorized access. In addition, wind fence also offers safety protection for personnel from the radiation of flare flame and from external surfaces of the combustion chamber.